Precision Die-Cutting: Your Vision, Our Reality.

Turn your designs into tangible pieces with our custom die-cutting service!

We offer precise and detailed cuts in a wide variety of materials, adapting to your specific needs.

How is our manufacturing process?

Initial Contact

We understand your needs: We ask clear and concise questions to understand exactly what the client needs.

Analysis and Quotation:

We evaluate the project: We analyze the files, materials and quantities required.

Client Approval

Quote Review: The client reviews the quote and requests any clarification needed.

Die Manufacturing:

Die Design: Based on the customer's files, our engineers design the die that will be used to cut the parts.

Quality control:

Visual Inspection: Each piece is inspected to verify that it meets quality standards.

Turn your designs into reality with our custom die-cutting service!

-

Precision:

Detailed cuts with minimal tolerances.

-

Versatility:

Wide variety of materials and thicknesses.

-

Quality:

Impeccable and long-lasting finishes.

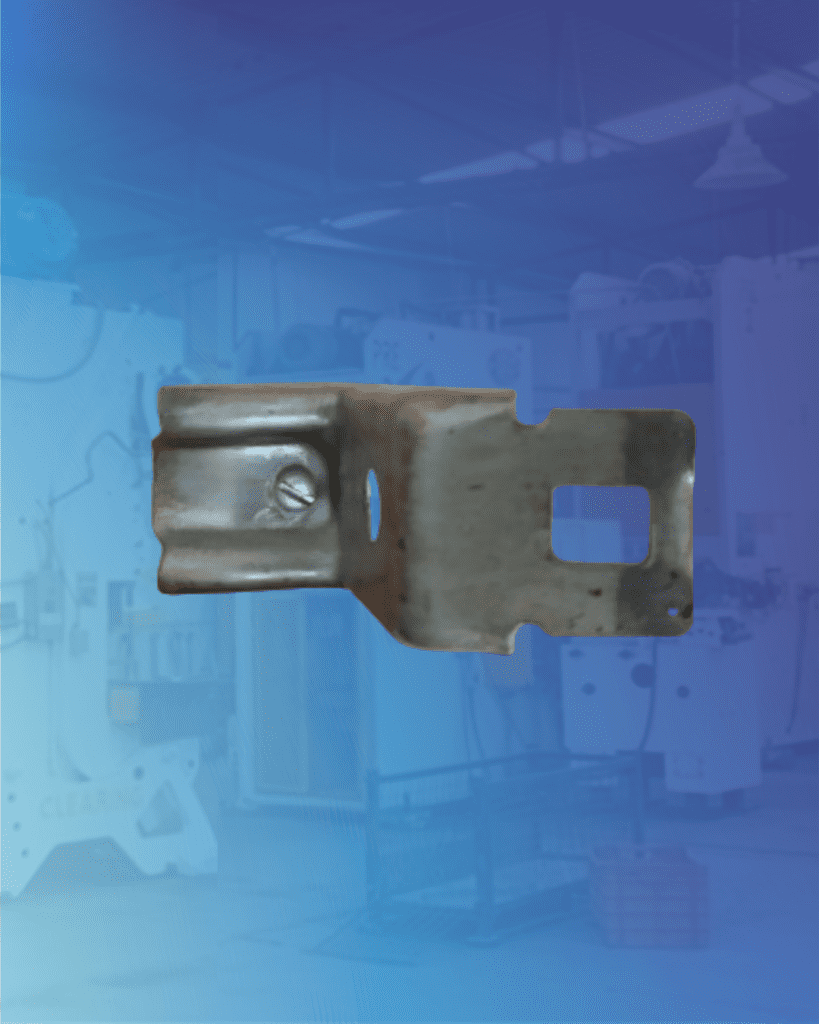

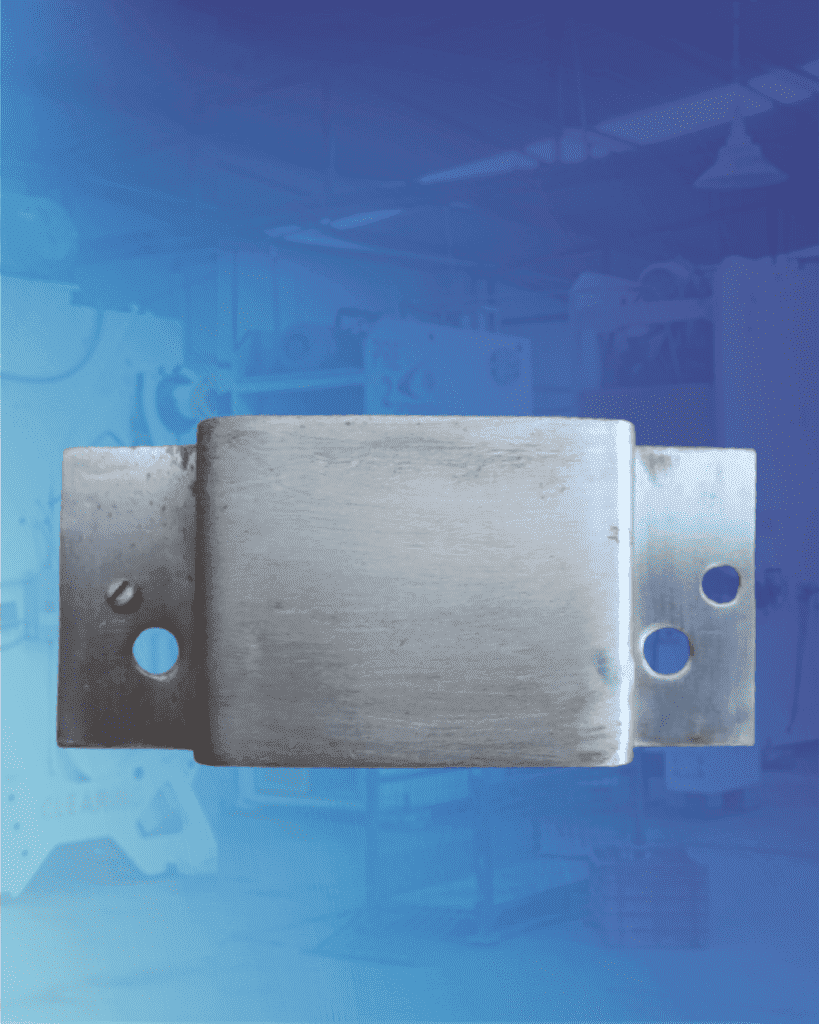

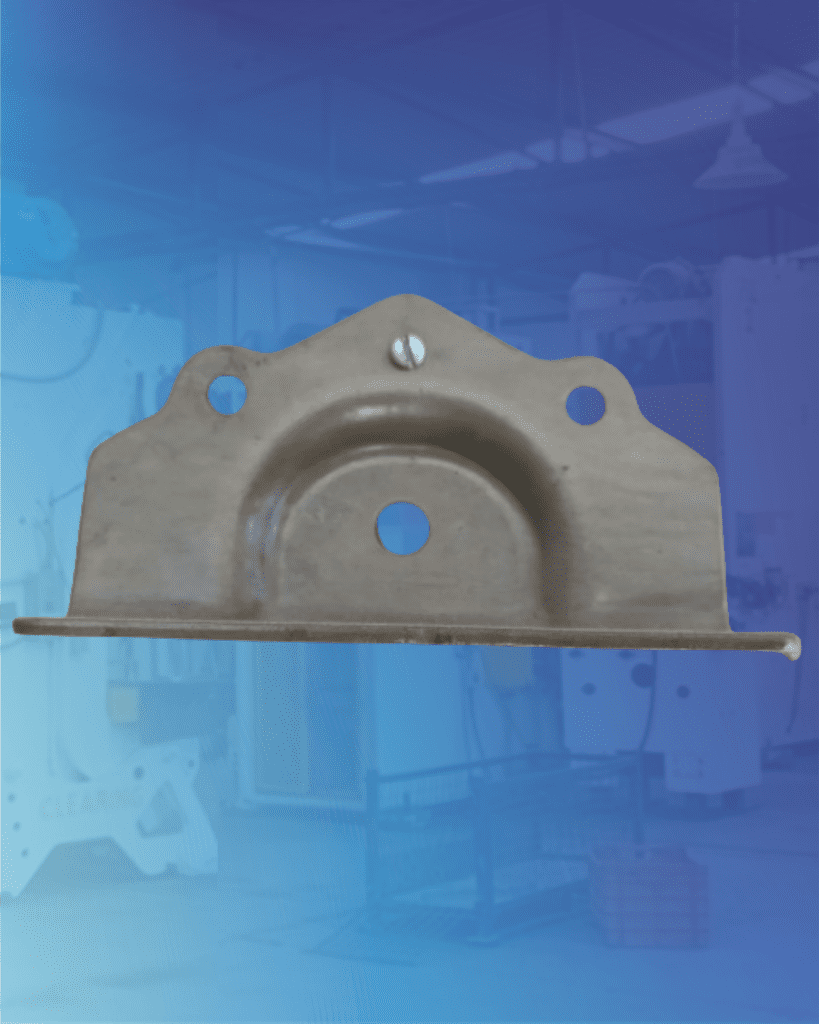

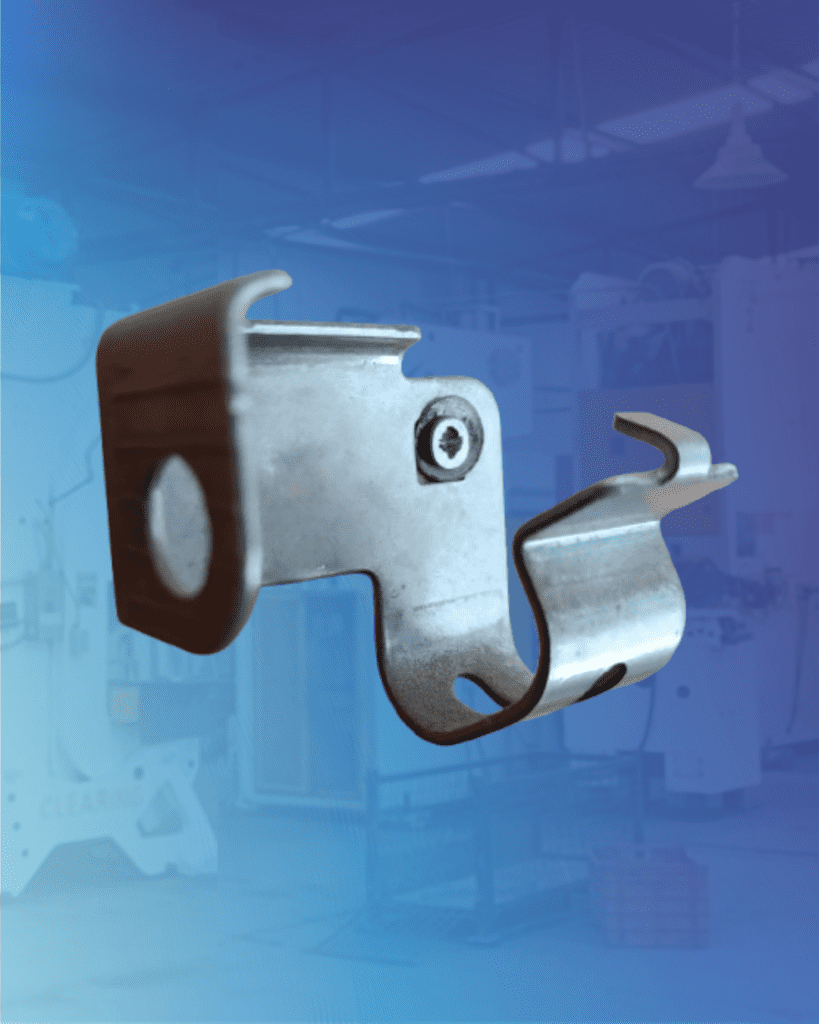

Our jobs

"We are equipped with the skills, human talent and machinery to offer you a variety of metal stamping solutions."

High volume applications:

We have the necessary infrastructure to meet any large-scale production requirement. Thanks to our warehouses and just-in-time delivery processes, Ditromex guarantees compliance with any delivery deadline.

Shopping:

We prioritize the quality of materials to achieve optimal results. We work in collaboration with your suppliers and our own network to select the best raw materials and offer superior solutions.

Equipment:

We have a large inventory of presses, complemented by auxiliary equipment such as overhead cranes, uncoilers, straighteners, feeders and in-line washers with rust-preventative applicators. The variety of openings, bed sizes and feeder options allows us to adapt to any need. Our presses can process steel coils of up to twenty tons, minimizing downtime due to changeovers.