From sheet metal to final product: a tour of the production process in a maquila

Hello everyone, lovers of engineering and industrial production. Today I want to take you on a fascinating journey through the process of die cuta fundamental technique in the manufacture of a wide variety of products. If you are a process engineer or a production manager In an assembly company, this article will be very useful to better understand how a simple sheet of metal is transformed into a functional and precise piece.

What is die-cutting and why is it so important?

Die-cutting is a cold forming process that involves cutting, bending or forming metal sheets using special tools called dies. Thanks to this technique, parts with very precise shapes and dimensions can be obtained, making it an essential process in industries such as automotive, electronics, household appliances and more.

The production process in a die-cutting factory

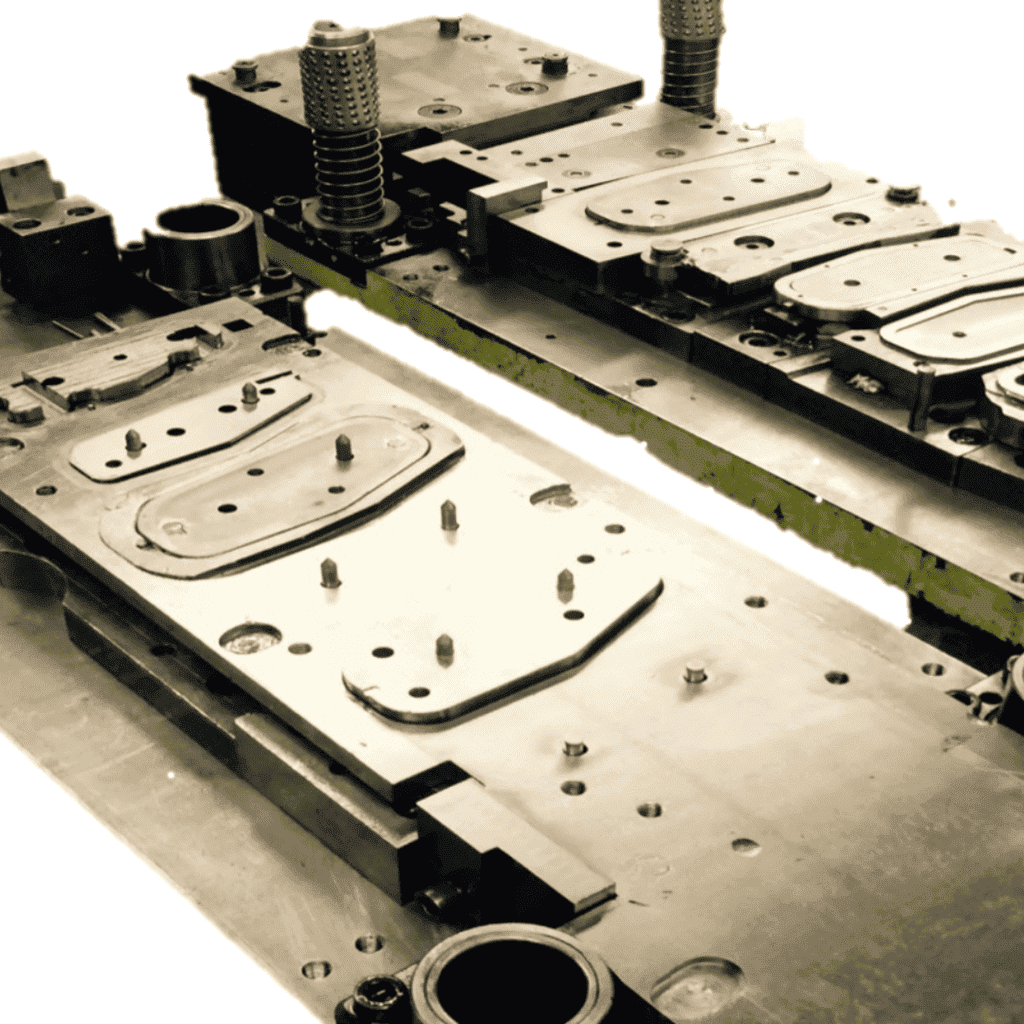

- Die design and development: It all starts with a detailed design of the part to be manufactured. From this design, a custom die is created, a precision tool that will be responsible for shaping the sheet.

- Material selection: Once the die is ready, the appropriate material is selected for the part, taking into account its mechanical properties and the requirements of the final product.

- Sheet feeding: The metal sheet is continuously fed into the press where the die is located.

- Forming of the piece: The die exerts a force on the sheet, cutting, bending or forming the piece according to the design.

- Quality Inspection: Each piece is thoroughly inspected to ensure it meets established quality standards.

- Acabado superficial: If necessary, surface finishing operations, such as polishing or coating, are performed to improve the appearance and properties of the part.

- Packaging and shipping: The finished parts are carefully packaged and shipped to the customer.

Why choose die-cutting for your production?

- Precision: Die cutting allows parts to be produced with very tight tolerances, which is essential in many applications.

- Repeatability: By using dies, large quantities of identical parts can be manufactured efficiently.

- Versatility: Die cutting can be applied to a wide variety of materials and thicknesses.

- Cost reduction: By automating the process, production costs are reduced.

Si estás buscando un socio confiable para tus proyectos de die cutDo not hesitate to contact us. At Ditromex, we offer solutions for precision die cutting a medida para satisfacer tus necesidades más exigentes.

Request your quote today and discover how we can help you optimize your production process!